Kandla, Gujarat (India) is home of IFFCO’s oldest production centre for Phosphates and NPK.

Two of the existing lines were commissioned back in 1999, based on Grande Paroisse‘s Dual Pipe Reactor technology (DPR), presently licensed by Casale after the acquisition in 2013 of the entire Nitrates and Phosphates technology portfolio from Grande Paroisse.

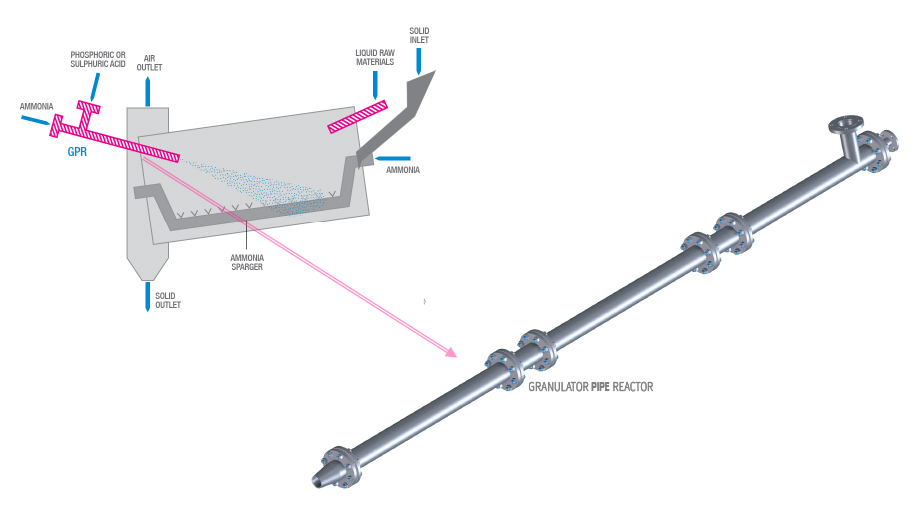

We are happy to announce that when IFFCO decided to debottleneck the two lines it opted for NitroPipe-X technologies and expertise. Casale will study the modifications required to boost the output by 15% to 25%, depending on the fertilizer grade to be produced, as well as furnish, for both lines, one new Pipe Reactor to replace the existing one in the granulator.

The new Granulator Pipe Reactor (GPR) is, in fact, central to the revamping approach devised by Casale as it allows to:

- Increase the phosphoric acid feed to the plant.

- Increase the N/P molar ratio.

- Minimize the impact on the scrubbing system as well as on the rest of the plant. In particular, the existing Pipe Reactor in the dryer (DPR) will be not replaced.

- Increase the overall plant flexibility of operation.

Last but not least, the new GPR can be easily fitted in existing granulator drums without major modifications.