During the CRU Nitrogen+Syngas 2026 Conference in Barcelona, Casale and Paralloy Group formalized a strategic Memorandum of Understanding (MoU), marking the beginning of a long-term collaboration aimed at redefining performance standards in steam methane reforming (SMR).

While the agreement centers on the joint commercialization of Paralloy’s advanced OMEGA® profiled reformer tube technology, both companies emphasized that the scope goes far beyond a single product. The partnership establishes an integrated approach combining advanced materials engineering with world-class process design expertise — with the objective of setting a new benchmark in reformer efficiency and capacity.

A Long-Term Vision for Next-Generation SMR Systems

Federico Zardi, CEO of Casale, commented:

“Today we are signing an agreement for the joint commercialization of an advanced product from Paralloy Group. But we see much more behind this MoU. Our objective is to build a long-term relationship, combining our respective strengths to bring the best solutions to the market for syngas generation and the production of ammonia, methanol, and hydrogen. We believe this complementary approach will position both companies further at the forefront of the industry”.

At the core of the collaboration lies the integration of Paralloy’s OMEGA® profiled reformer tubes with Casale’s advanced reformer process design and plant-wide optimization expertise.

Casale contributes decades of experience in SMR design, syngas integration, and performance optimization across ammonia plants, methanol units, hydrogen production facilities, and refinery applications worldwide. This integrated know-how ensures that innovation at the component level is fully embedded within the overall process configuration, enabling tangible gains at both system and plant level.

Setting a New Benchmark in Capacity and Efficiency

Through this alliance, Casale and Paralloy Group are not pursuing incremental improvements — they are redefining the performance envelope of primary reformers.

By combining optimized metallurgy and geometry with advanced process engineering, the partnership enables:

- Higher throughput and capacity beyond conventional design limits

- Superior reaction rate efficiency

- Significantly lower tube metal temperatures

- Reduced fuel consumption

- Extended equipment lifetime

This system-level integration allows reformers to operate at performance levels previously unattainable with standard configurations.

The result is a structural leap in energy efficiency.

Lower fuel consumption directly translates into reduced operating costs — and, as a direct consequence, lower CO₂ emissions.

In this way, sustainability becomes an outcome of superior engineering performance.

Supporting Energy-Intensive Industries Worldwide

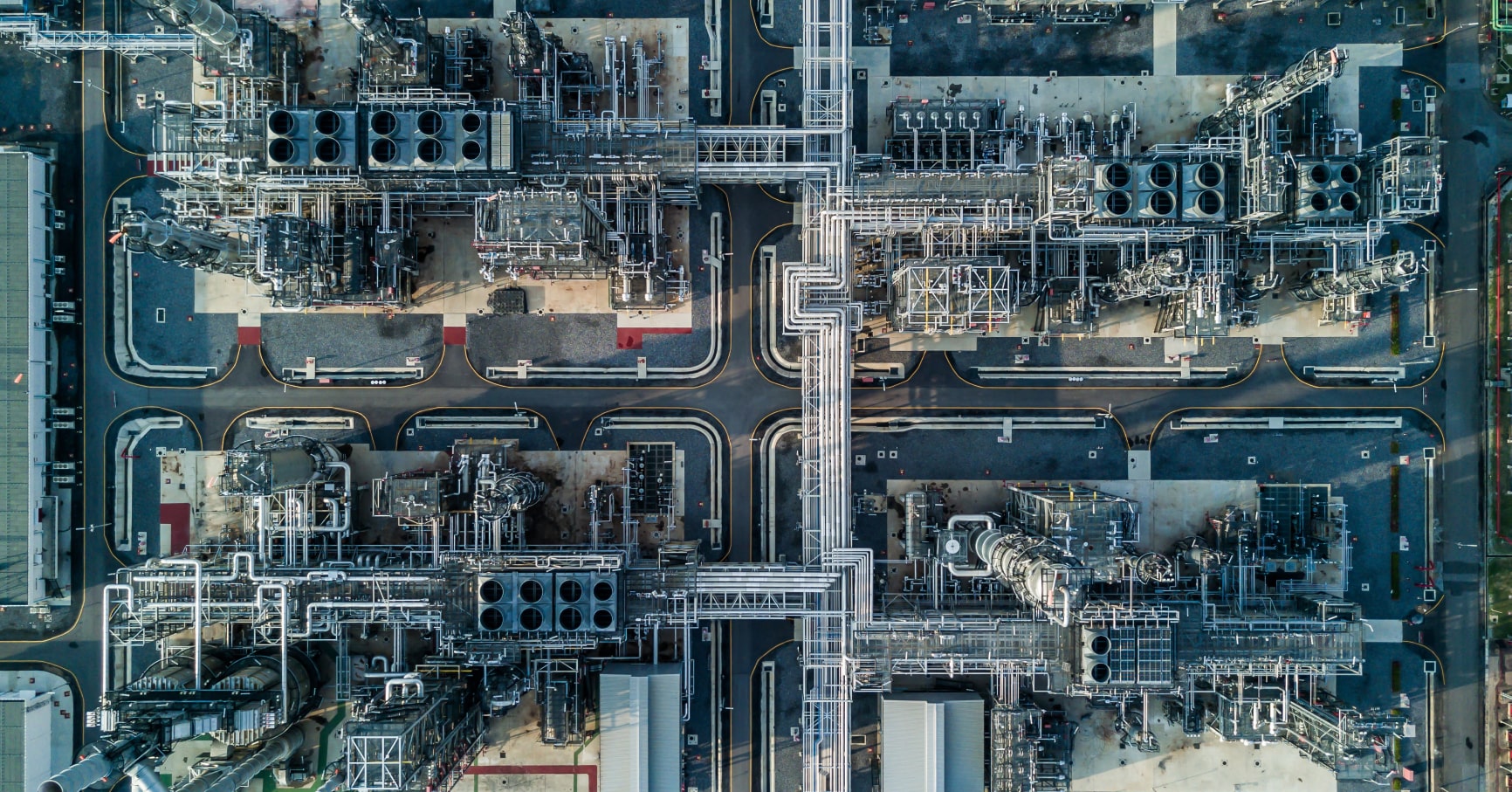

Steam methane reforming remains a cornerstone technology for hydrogen production and syngas generation in:

- Ammonia plants

- Methanol units

- Refineries requiring high-purity hydrogen

- Petrochemical complexes

- Emerging low-carbon hydrogen projects

Improving reformer efficiency has a direct impact on plant economics, competitiveness, and environmental performance across these sectors.

Robert McGowan, CEO of Paralloy Group, added:

“At Paralloy Group, our cultural pillars are Innovation, Excellence, and Commitment. This partnership represents all three. Together, we bring cutting-edge material solutions and engineering expertise that can make a transformative difference for our customers. This is not just a commercial agreement — it is a commitment to deliver something truly unique to the market”.

A Shared Commitment to Performance Leadership

The MoU reflects a shared ambition: to combine hardware innovation and process excellence into a fully integrated SMR solution capable of delivering unprecedented efficiency gains for energy-intensive industries.

By aligning advanced materials technology with deep process engineering expertise, Casale and Paralloy Group aim to define the next generation of high-performance reformers — where operational excellence, energy efficiency, and sustainability advance together.

Discover Casale’s Hydrogen & Syngas Solutions

To learn more about Casale’s technologies for hydrogen production, syngas generation, reformer optimization, and applications in ammonia plants, methanol units, and refineries, visit our dedicate page.