We are pleased to announce that Chambal Fertilisers and Chemicals Limited (CFCL), one of India’s leading agrochemical producers, has selected Casale’s proprietary technologies for its new Technical Ammonium Nitrate (TAN) complex in Gadepan (Kota), India, scheduled for commissioning in Q4 2025.

The complex is being built on a License & EPC basis by Larsen & Toubro Energy Hydrocarbon Division (LTEH) under a fast-track 30-month execution timeline. Casale, leveraging its complete nitrate technology portfolio, has supplied the License, Process Design Package, Proprietary equipment, and the review of key engineering documents for the entire complex, whilst LTEH’s serves as the main EPC contractor.

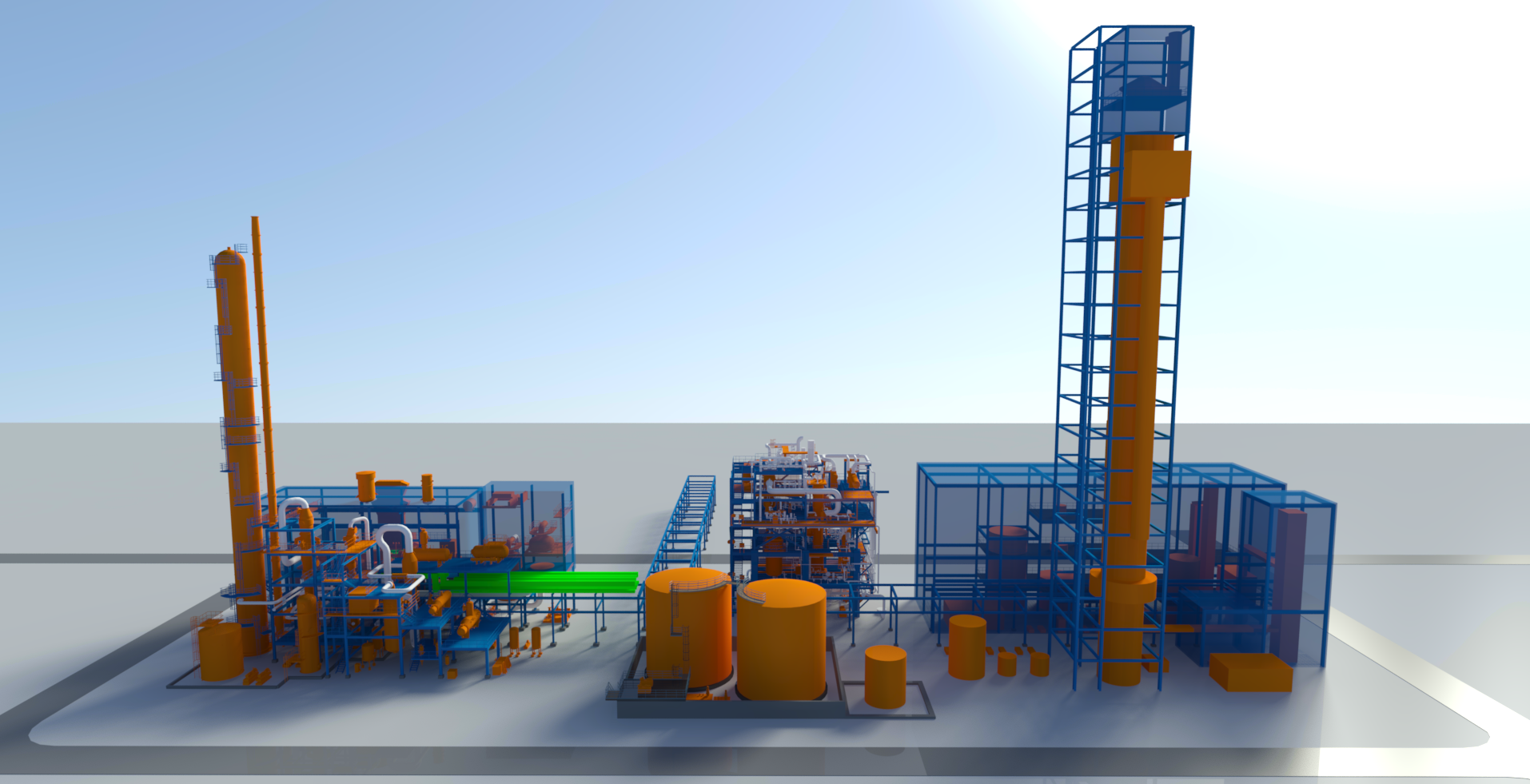

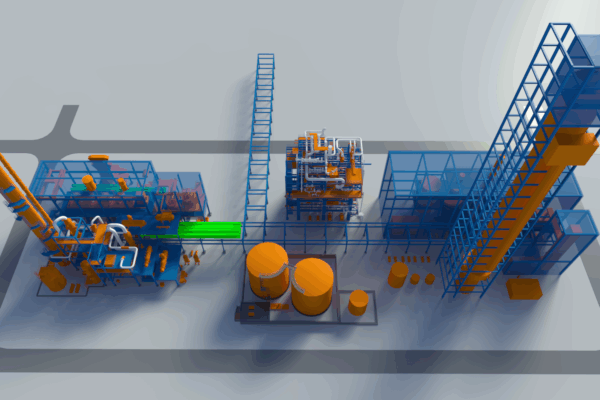

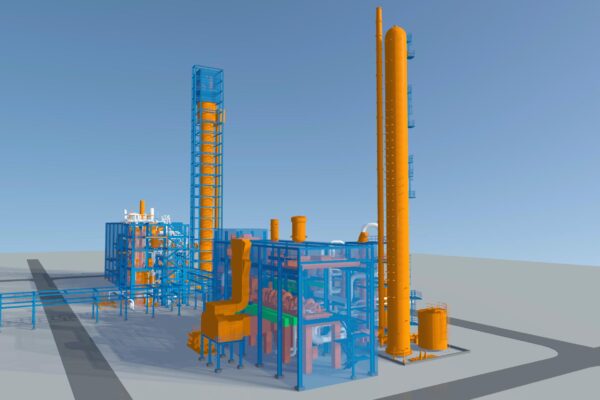

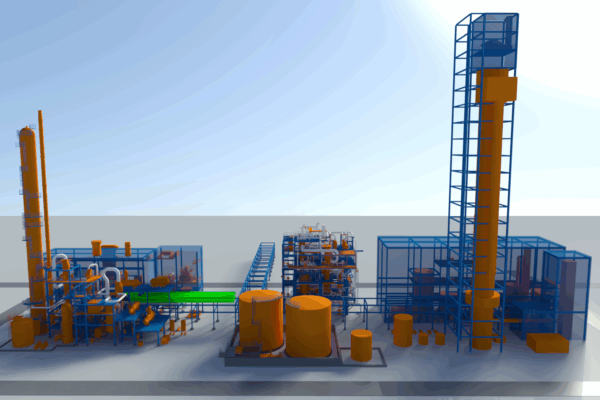

An Advanced Technological Setup

The new facility integrates three of Casale’s proprietary technologies, forming a complete and fully optimized nitrate production chain:

- A 600 MTD Weak Nitric Acid (WNA) plant, utilizing Casale’s proprietary DualPURE™ (Dual Pressure) process;

- A 700 MTD Ammonium Nitrate Solution (ANS) plant, featuring Casale’s NitroPIPE™ Pipe Reactor technology;

- A Technical Ammonium Nitrate (TAN) prilling unit, delivering high-quality, uniform prills.

This project will contribute significantly to India’s self-sufficiency in the production of nitrates, the reducing dependency on imports and meeting the country’s rising demand in agriculture and industrial sector.

Why Casale

Casale’s DualPURE™ WNA technology was selected for its maturity, safety, and high-reliability design. Key benefits include:

- Lowest ammonia consumption

- Minimized PMG operating losses and extended campaign lengths

- Best-in-class energy efficiency

- Lowest emissions and effluent discharge

Casale’s Ammonium Nitrate technology also provides significant advantages, particularly, in safety by design, which is critical for mitigating the risk of uncontrolled decomposition—a leading cause of accidental explosions in similar facilities.

The prilling unit further enhances performance with:

- Homogeneous particle size distribution

- Simplified effluent handlig

- High degree of energy integration

By integrating these complementary technologies, the plant benefits from extended uptime and long-term operational stability, reduced emissions for full environmental compliance, and overall cost-effective performance —directly supporting India’s ambition for a reliable and sustainable production system.