With over 100 years of experience, Casale is a key player in the transition to a green future. We offer our impressive expertise in manufacturing new plants, revamps, equipment, and services for ammonia technology.

AMMONIA

New plants

Flexigreen

FlexAMMONIA

Green Ammonia synthesis loop for large capacities

MIX-N

Tailor made solutions for green hydrogen integration

SMART-N

Green Ammonia synthesis loop for small capacities

Flexiblue

HyPURE-N

Syngas combined reforming

N-ELEVA BLUE

Steam-methane based process for Blue ammonia

Traditional Solutions

N-ELEVA

SMR process

N-LOOP

Ammonia synthesis loop

SynPOWER-N

Syngas combined reforming

FlexAMMONIA

Casale's cutting-edge solution for large-scale Green Ammonia synthesis plants

FlexAMMONIA, is the cutting-edge solution from Casale for large-scale green ammonia synthesis plants. Designed with a paramount focus on energy efficiency, FlexAMMONIA stands as a forefront solution in sustainable ammonia production.

It utilizes hydrogen derived from water electrolysis with renewable energy and pure nitrogen from an air separation unit.

FlexAMMONIA boasts a remarkable capacity rangeability and the ability to operate reliably, even with fluctuating renewable power supplies.

Performances

- Clean Syngas consumption, per ton of ammonia produced: ~2650Nm3 (equivalent to less than 2000 Nm3 of H2)

- Reaction heat recovery, per ton of ammonia produced: more than 600’000 Kcal

- Plant turndown range: 10-100%

- Ramp-up/down rate: up to 3%/min

Technical Brochure

News & References

HyPURE-N

Casale's pure ATR-based process for large-scale Blue Ammonia plants

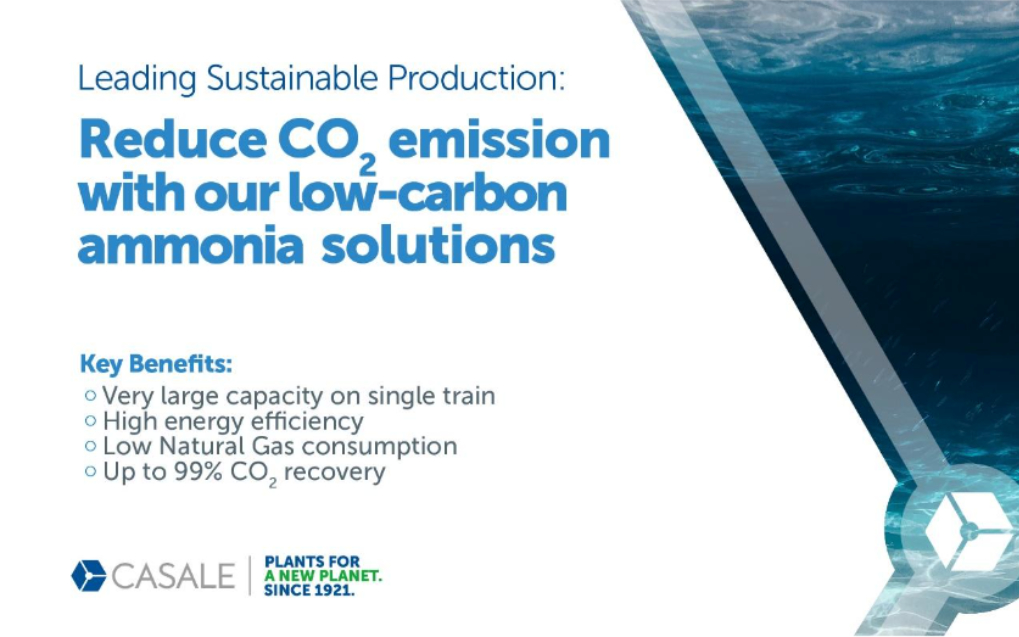

Casale has embraced the energy transition challenge focusing on developing sustainable technologies for the production of various base chemicals, including blue ammonia from Natural Gas resources.

Drawing upon proprietary technologies, HyPURE-N represents the latest step forward for the large-scale production of ammonia with a greatly reduced environmental impact thanks to the optimization of the energy consumption, the reduction of the natural gas required thus generating, as a consequence, a lower amount of emissions. All CO₂ is captured, and it is sent to sequestration or to other utilizations.

Performances

- Energy consumption: as low as 7.4÷7.6 Gcal/MT LHV basis, including utilities and final CO2 compression at Battery Limits

- CO2 recovery: as high as 99%

- Capacity: best suited from 3,500 MTD and higher, but can be applied also for lower capacities

Technical Brochure

News & References

MIX-N

Casale's solution to decarbonize existing Ammonia plants through the integration of Green Hydrogen

MIX-N, part of the FLEXIGREEN® range of sustainable products, is Casale concept specifically devised to enable the integration of any existing plant with green hydrogen supply.

The MIX-N concept stands out for its simple and reliable arrangement.

It operates the plant front-end under near steady conditions, while the synthesis loop load flexibly fluctuates in response to the variability of renewable energy supply. This approach avoids any cyclic operation, ensuring a wide range of production adaptability.

Benefits

- Lower Energy consumption. As a general rule, the Natural

Gas consumption is inversely proportional to the extent of hybridization, that is, for each percentage of green H2 in the total H2 fed to the plant, the NG specific consumption reduces by approximately by 1% - The Electrical energy consumption is increased on account of the increased demand for green H₂ production

- Significant production turn-down: 10-110%

Technical Brochure

News & References

N-ELEVA

Casale's SMR-based Ammonia process for world-scale traditional plants

N-ELEVA is Casale process for traditional ammonia plants, based on steam-methane reforming (SMR) of natural gas. One of the notable features of N-ELEVA Process is its adaptability to meet the specific needs of our clients, with the added benefit of an easy integration into downstream units.

Performances

- About 110 mg/Nm³ of NOx as per standard scheme, lower number are possible with proper burner solution

- Energy consumption up to 6.5 Gcal/MT (grey configuration)

- Blue configuration has energy consumption from 7.9 Gcal/MT

Technical Brochure

News & References

N-ELEVA BLUE

Casale's SMR-based Ammonia process for world-scale Blue plants

N-ELEVA BLUE is Casale process tailored for blue ammonia plants, based on steam-methane reforming (SMR) of natural gas.

One of the notable features of N-ELEVA BLUE is its adaptability to meet the specific needs of our clients, with the added benefit of easy integration into downstream units.

Performances

- About 110 mg/Nm³ of NOx as per standard scheme. Lower concentrations are possible with proper burner design

- CO2 emissions up to 0.1-0.15 t CO2/t NH3

- Energy consumption up to 6.6-6.8 Gcal/MT LHV basis

Technical Brochure

News & References

N-LOOP

Casale's Ammonia synthesis loop for inert-free syngas

Producing ammonia from coal requires coal-gasification technology to generate the syngas. The plant differs significantly compared to a natural gas based one, being more complex and costly.

For coal-based plants, third-party licensors are provide the coal gasification, while Casale offers with its own unique N-LOOP ammonia synthesis technology complemented by the optional integration of the Axial-Radial® CO-shift section in the purification section of the front-end.

The use of the proprietary Amomax® Casale catalyst for ammonia synthesis complete the offering, for improved efficiency and performances.

Performances

- Clean syngas consumption, per ton of ammonia produced:~2’650Nm3 (or <2’000 Nm3/MT of H2)

- Reaction heat recovery: more than 600’000 Kcal/MT of ammonia

Technical Brochure

News & References

SMART-N

Casale's solution for small Green Ammonia synthesis plants

SMART-N is Casale sustainable solution for small green ammonia synthesis plants, whose feedstock

is hydrogen produced via water electrolysis using renewable energy and pure nitrogen obtained in an air separation unit. This process scheme can be easily customized to meet specific Client’s needs and adapted also for other applications such us in case of small blue or turquoise ammonia plants.

A distinctive feature of this process lies in its wide capacity rangeability and, if required, it can reliably operate with an erratic renewable power supply so to avoid or minimize the negative effects of cyclic operation

and fatigue.

Performances

- Loop turndown ratio, from 10% to 110%

- Energy consumption: about 300 kWh/MT

- No demi-water consumption

Technical Brochure

News & References

SynPOWER-N

Casale's combined reforming process for large-scale traditional Ammonia plants

SynPOWER-N is a single-train process tailored for 3,500 to 10,000 MTD of ammonia, achieving peak capacity and maximizing economies of scale while still ensuring that all critical items are fully referenced at the size required.

Performances

- Net gas consumption: less than 6.5 Gcal/MT of ammonia (27 GJ/MT)

- Optionally, balanced ammonia and CO2, for total conversion to urea, and higher urea production

- Compared to a traditional process: 25% less CO2 emissions at the stack, 30% less plot space, 50% less catalyst volume and reduces the required operator count by 50%

Technical Brochure

News & References

Ammonia Revamping

We excel at providing customized solutions for ammonia plant upgrades. We use our experience to implement specific plant upgrade technologies to increase production, optimize energy use and reduce the carbon footprint.

Equipment

We bring more than four decades of expertise and innovation to designing and manufacturing reactors and critical equipment for the industries we serve, both for new plants and for revamping existing facilities. We are committed to the highest quality standards in every project, delivering superior performance and ensuring long-term reliability. Our unwavering commitment is to deliver exceptional value to our customers consistently.

Casale & Arvos

Process Gas Coolers Brochure

Services

Casale’s ammonia services integrate advanced catalyst assessment and steam reforming expertise. Tailored to enhance operational efficiency, our solutions embody innovation and precision, ensuring plants meet the demands of modern production.

- Analysis of operating data and Performances assessment

- Troubleshooting

- Residual Catalyst life assessment

- Chemical analysis of spent catalyst for detection of contaminants

Catalyst assessment

- Reformer simulation

- Radiant and convection sections efficiency assessment

- Troubleshooting

- Radiant tubes inspection

- Metallurgical investigation and refractory materials analysis

- Coil and transfer line modifications

Steam reformers

- Technical supervision of catalyst maintenance work

- Replacement of ammonia synthesis catalysts:

- issue of procedures

- technical supervision of the works

- catalyst replacement work on request

- Radioisotope testing of ammonia converters for internal leak detection or bypass (in collaboration with specialized companies)

- Design and maintenance of electrical start-up heaters of ammonia converter

Other services

Applications

Driving the green revolution and building a sustainable future

Traditional uses:

Ammonia is the sole source for producing:

All nitrogenous fertilizers

Various chemicals including caprolactam, melamine, ethanol amines, acrylonitrile and other organic products

Blasting agents

Emerging uses:

Ammonia is used directly as:

H2 carrier

Bunker fuel

Energy storage for grid stabilization

Base to produce green fertilizers

Ammonia for life

Read the synthesis of ammonia and the birth of modern chemistry